Quality Assurance

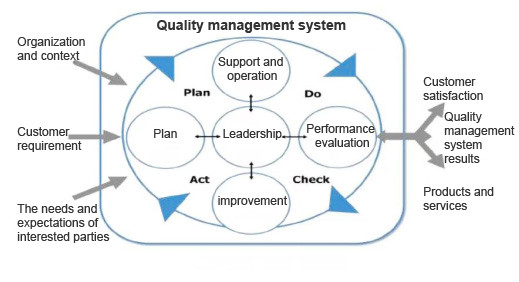

The company adopts the PDCA cycle shown in the figure below and risk-based thinking to manage the process and system as a whole, so as to effectively utilize the opportunities and prevent the occurrence of unintended results, and the model covers all the processes of the company.

In accordance with the requirements of IATF16949 quality management system, strict procedures, scientific production, to ensure that the qualification rate of the products leaving the factory reaches 100%, obtaining ISO9001, IATF16949 quality management system certification, CCC, GCC, SASO, ECE-R30, ECE-R54, ECE-R117 a total of six categories of 109 product certification certificates. It can meet the sales demand of more than 100 countries and regions. In 2012, the brand "Duraturn" was recognized as "Famous Trademark of Xianyang City" and "Famous Trademark of Shaanxi Province"; "Duraturn" products were recognized as "Famous Trademark of Xianyang City" and "Famous Trademark of Shaanxi Province" in 2013. In 2013, "De'an Tong" brand products were recognized as "Xianyang City Characteristic Brand Products" and in 2014, they were named "Shaanxi Province Famous Brand Products".

It has won the national and industry-related honors such as 3-15 International Consumer Rights Day and September National Quality Month, etc. In 2023, it declared itself as a finalist of Xi'an Quality Benchmarking Cultivation Enterprise, and in the cultivation period, it constantly and systematically summarized and condensed the work of quality management improvement in recent years in combination with the company's actuality, and in June 2024, it declared itself as Xi'an Quality Benchmarking Enterprise.

In order to strengthen the quality control of the production process, from the raw materials into the factory to the finished products out of the factory to form a production line staff self-inspection, mutual inspection between the positions, quality assurance personnel special inspection, management personnel inspection of the organic unity of the four. The company has formulated a comprehensive quality management system of "rewarding and penalizing" to encourage each process to strictly control the quality and prevent the flow of non-conforming products into the next process, and resolutely achieve the goal of not accepting defective products, not manufacturing defective products, and not transmitting defective products.

Official Wechat

Official Wechat Duraturn Tyre

Duraturn Tyre Neolin Tyre

Neolin Tyre Yangchang Online Store

Yangchang Online Store Office OA

Office OA